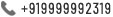

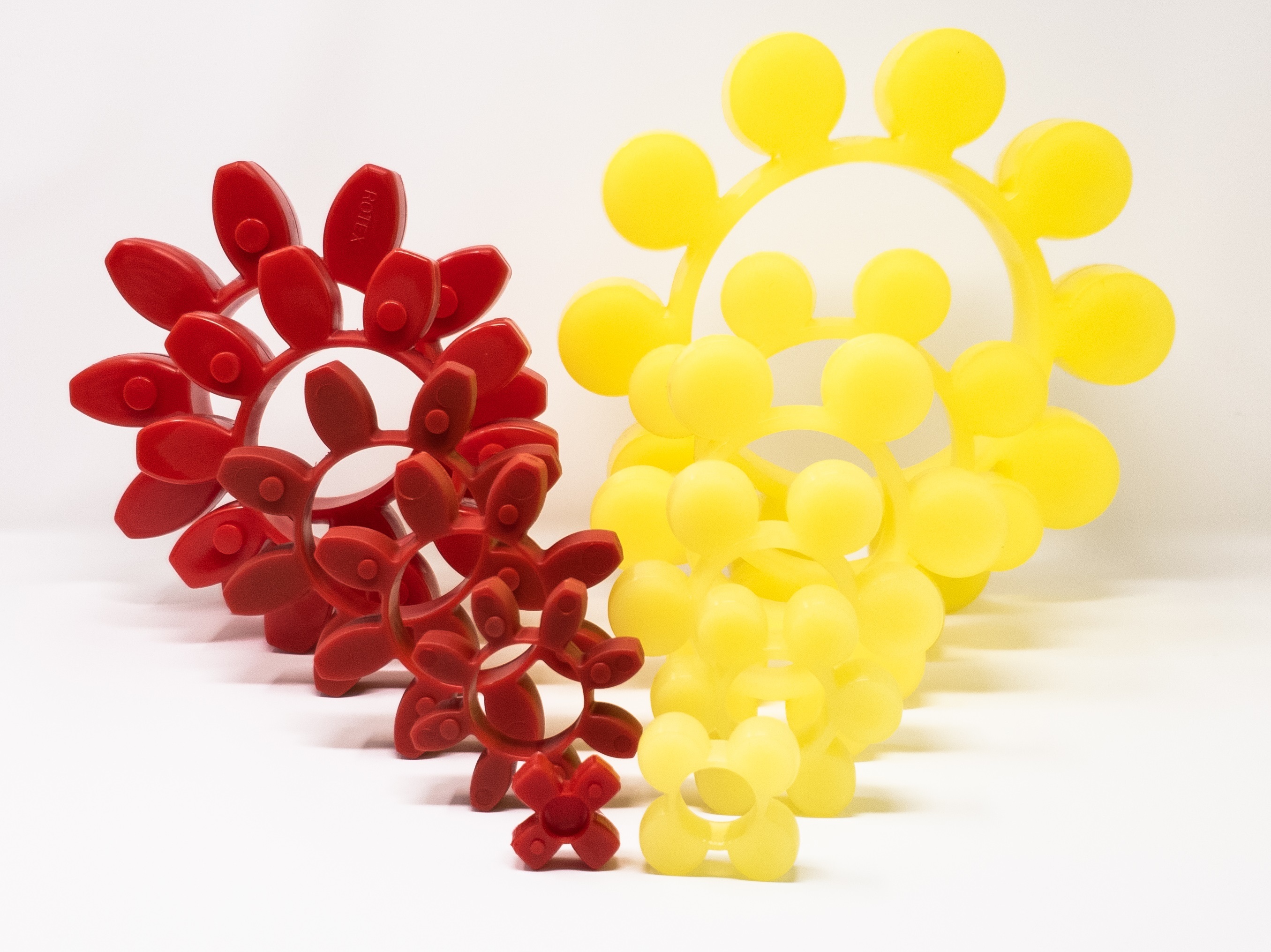

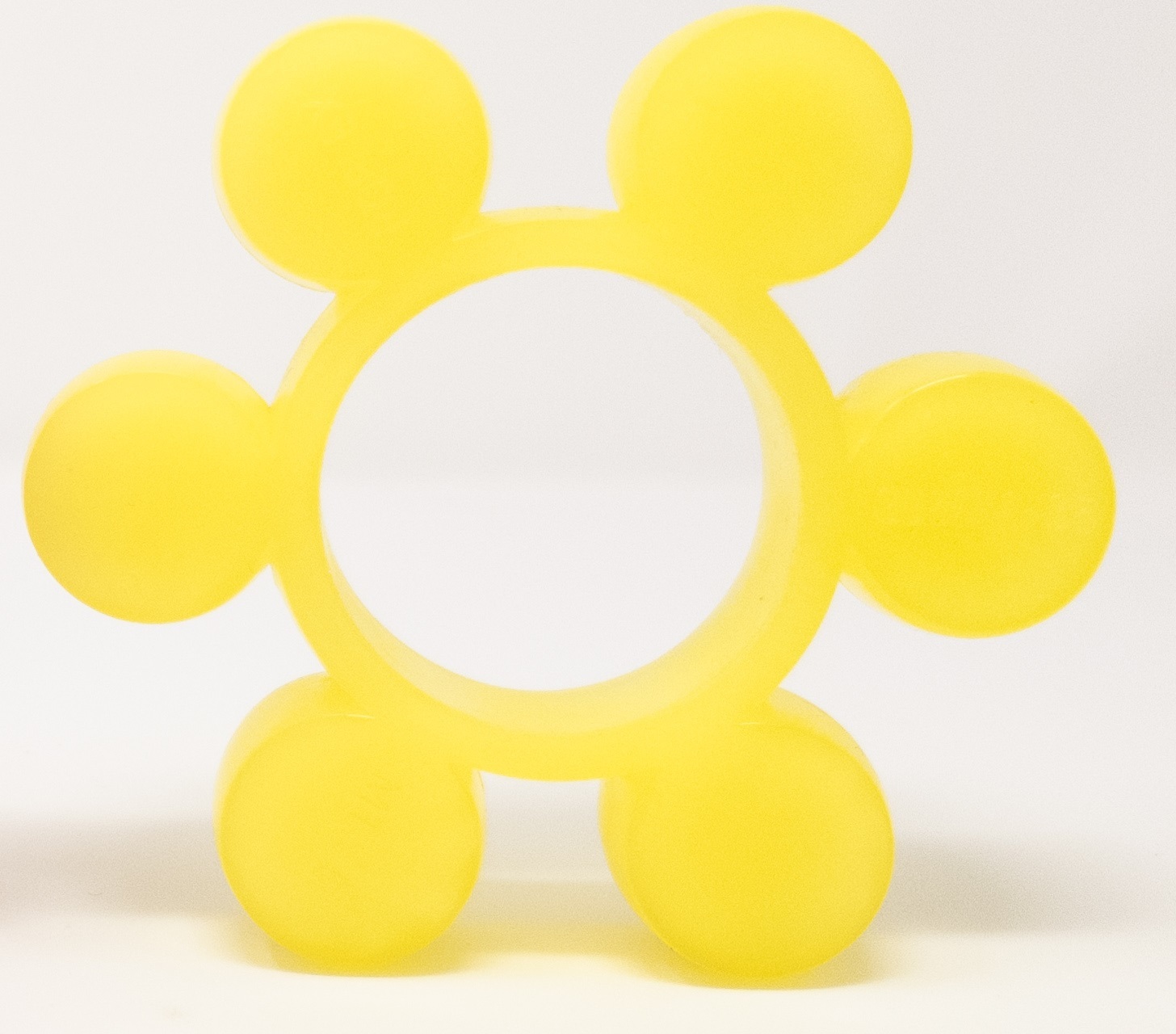

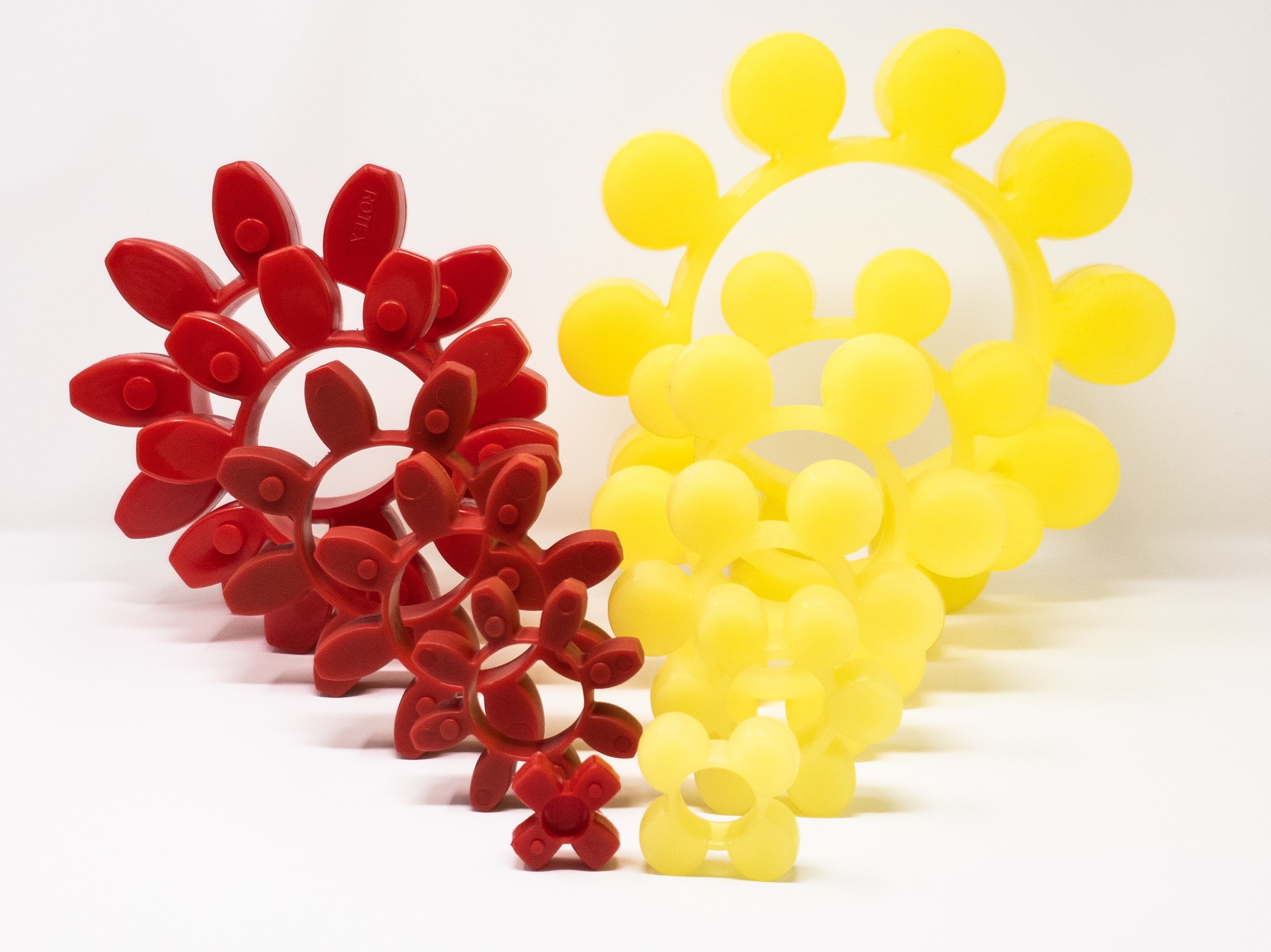

Spider Couplings

200 INR/Piece

Product Details:

- Surface Finish Polished

- Natural Rubber Yes

- Diameter 2 to 4 mm Millimeter (mm)

- Feature Light Weight

- Usage & Applications Industrial

- Material PU

- Click to View more

X

Spider Couplings Price And Quantity

- 20 Piece

- 200 INR/Piece

- 200.00 - 2000.00 INR/Piece

Spider Couplings Product Specifications

- PU

- Industrial

- Yes

- Polished

- 2 to 4 mm Millimeter (mm)

- Light Weight

Spider Couplings Trade Information

- Delhi

- 100 - 1000 Piece Per Day

- 10-30 Days

- Sample costs shipping and taxes has to be paid by the buyer

- Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal, Gujarat, Central India, Odisha, Chhattisgarh, All India

Product Description

Spider Couplings

Power machinery are mostly connected to working machines by flexible couplings (spiders) to achieve the functional cushioning and vibration-reduction.

Spider Coupling is used as a joint in transmission shaft for jaw coupling,

Key feature

- Easy installation

- Standard insert can handle large temperature range from -40 to 80 C.

- High tear and abrasion resistance

- High processing precision

- Material : Polyurethane

Versatile Applications in Indian Industry

Spider couplings are extensively used across various industries in India, including manufacturing, automation, and processing plants, due to their adaptable design and robust construction. Their lightweight nature and polished finish make them ideal for environments requiring both durability and precision.

Quality Materials for Enhanced Performance

Manufactured from premium polyurethane and natural rubber, these couplings provide excellent resilience and flexibility. Their composition ensures outstanding vibration absorption and wear resistance, which translates into longer operational lifespan and reduced maintenance costs.

FAQs of Spider Couplings:

Q: How are spider couplings installed in industrial machinery?

A: Spider couplings are typically mounted between two shafts to ensure torque transmission and accommodate slight misalignments. Installation involves securing the coupling elements onto each shaft, aligning them precisely, and tightening the fasteners as recommended by the manufacturer.Q: What makes polyurethane and natural rubber suitable materials for spider couplings?

A: Polyurethane and natural rubber offer superior flexibility, abrasion resistance, and vibration damping. These qualities help the couplings withstand rigorous industrial use, minimize wear, and ensure consistent performance over time.Q: When should you consider using spider couplings in your equipment?

A: Spider couplings are recommended whenever torque needs to be transmitted between shafts with minor misalignments, especially in environments that require flexible, lightweight, and reliable connectors. They are suitable for both new installations and equipment upgrades.Q: Where can spider couplings be sourced in India?

A: These spider couplings are readily available from various distributors, exporters, manufacturers, suppliers, traders, and wholesalers throughout India. Buyers can contact reputable firms specializing in industrial components for procurement.Q: What is the process for maintaining spider couplings to ensure long operational life?

A: Regular inspection for wear, alignment, and tightness is crucial. Periodic cleaning, lubrication (if required for the application), and timely replacement of worn elements help keep the coupling performing optimally and prolong its lifespan.Q: What are the key benefits of using polished, light-weight spider couplings?

A: A polished surface finish reduces friction and minimizes contamination, while the lightweight design simplifies handling and installation. These benefits culminate in enhanced machinery efficiency and reduced downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'POLYURETHANE PRODUCTS' category

|

PARAKH RUBBER HOUSE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |